In the modern world of electronics, circuit boards play a main role, working as the foundation of nearly every gadget we rely upon, from smartphones to sophisticated commercial equipment. At the heart of these innovations is the printed circuit board (PCB), an essential part that connects numerous electronic components and assists in the procedure of electronic circuits. The need for top quality PCB fabrication and assembly has actually risen, bring about the emergence of various PCB manufacturers around the world. The variety in sorts of motherboard, such as flexible PCBs, rigid-flex motherboard, and high-density interconnect (HDI) PCBs, satisfies the different requirements of markets varying from consumer electronics to telecommunications.

Their design and assembly are essential, and companies that specialize in PCB assembly typically offer a range of services including prototyping, production, and assembly of these vital components. By utilizing innovative PCB manufacturing strategies, manufacturers are qualified of producing circuit boards that fulfill the stringent demands of high-frequency applications, such as those located in radio frequency (RF) communication circuits.

The process of PCB assembly typically involves several key stages, including soldering components to the PCB, testing for quality guarantee, and ensuring the last item fulfills both governing requirements and client requirements. In addition, the surge of quick turn PCB services has considerably reduced the lead time for manufacturing circuit boards, permitting companies to introduce faster and bring products to market more promptly.

The capacities of manufacturers have expanded to include not just common PCB assembly but likewise custom PCB options, permitting organizations to bring their unique designs to life. Custom PCB fabrication services enable clients to specify the accurate dimensions, layer count, and materials needed for their job, guaranteeing compatibility with a variety of electronic designs.

Flex PCBs, or flexible printed circuits, stand for an additional specialized location within the PCB sector. These boards can twist and bend, making them optimal for applications where area is restricted or where standard rigid boards might not fit. The advancement of flexible PCB innovation has opened up brand-new opportunities in item design, specifically in smart phones, wearable innovation, and medical devices. Flexible circuit boards usually feature the benefits of lightweight construction, reduced room requirements, and the capacity to incorporate several functions within a solitary device, making them a prominent choice amongst engineers and designers.

Effective multilayer PCB assembly demands exact placement and careful consideration during the design phase to stop signal disturbance and make sure optimum efficiency. Advanced techniques, like blind and buried vias, have emerged to meet these complexities without compromising the efficiency and functionality of the PCB.

Another important consideration in PCB engineering is impedance control, which is crucial for ensuring signal integrity, especially in high-speed applications. Designers must carefully analyze the physical layout of circuit traces, the product residential or commercial properties of the PCB, and the connection techniques to keep constant impedance across the board. Integrating these concepts right into PCB design not only enhances efficiency however also adds to the integrity of communication circuits and high-frequency applications.

For companies looking to enhance their PCB production process, turnkey PCB assembly services can be a perfect service. This approach not just reduces the time needed to turn design concepts into completed items but likewise streamlines supply chain management by minimizing the demand for multiple vendors.

The competitors amongst PCB manufacturers has led to an enhanced concentrate on high quality and advancement, with several firms applying rigorous quality assurance processes to guarantee their motherboard fulfill sector standards. Certifications like IPC-A-610, which regulates the acceptability of electronic assemblies, play an important duty in ensuring consumers of the reliability and durability of their products. Manufacturers must rely upon state-of-the-art evaluation technologies, such as automated optical evaluation (AOI) and X-ray analysis, to spot defects early in the production process, thereby reducing waste and improving total product top quality.

The environmental influence of PCB production has likewise become a considerable concern in current years. As businesses end up being extra environmentally mindful, PCB manufacturers are taking on sustainable methods, consisting of the use of green materials and the application of waste decrease campaigns. Additionally, policies pertaining to the disposal of electronic waste, such as the European Union's RoHS directive, have influenced manufacturers to lessen making use of hazardous compounds in their items, promoting an industry-wide change towards greener production approaches.

In the world of innovation, recent improvements in PCB modern technology have introduced amazing opportunities. As electronics continue to develop, so as well does the significance of innovative techniques to PCB design and manufacturing.

Small prototyping has actually also evolved substantially, allowing companies to check designs quickly before devoting to larger production runs. Prototyping not only allows designers to determine prospective design problems however additionally gives a possibility for optimization, making it possible for customized adjustments that can make a considerable difference in the final efficiency of an electronic tool. The capacity to deliver top quality prototypes in a short duration enhances the fast speed of product growth that identifies today's innovation landscape.

The rich selection of PCB designs, ranging from circuit card assemblies to specialized high-frequency designs, underscores the important role that these boards play in making it possible for the performance of modern-day electronics. With continuous advancements in manufacturing innovations, flexible designs, and product sciences, the future of PCB production looks encouraging.

Finally, from the standard circuit board to the very advanced multilayer designs and flexible circuits that adjust to innovative applications, printed motherboard represent the core of electronics. The adaptability, integrity, and performance of these components continuously drive sectors to seek exceptional capacities in PCB manufacturers. With the most recent developments in modern technology, the production of PCBs is becoming more effective, eco-friendly, and customized to the evolving needs of a progressively electronic globe. As we look in advance, the assimilation of brand-new products, designs, and fabrication techniques will certainly play a critical function in custom circuit board manufacturers transforming exactly how we engage with innovation, paving the method for innovative electronic applications in the years to come.

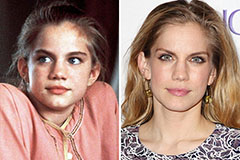

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!